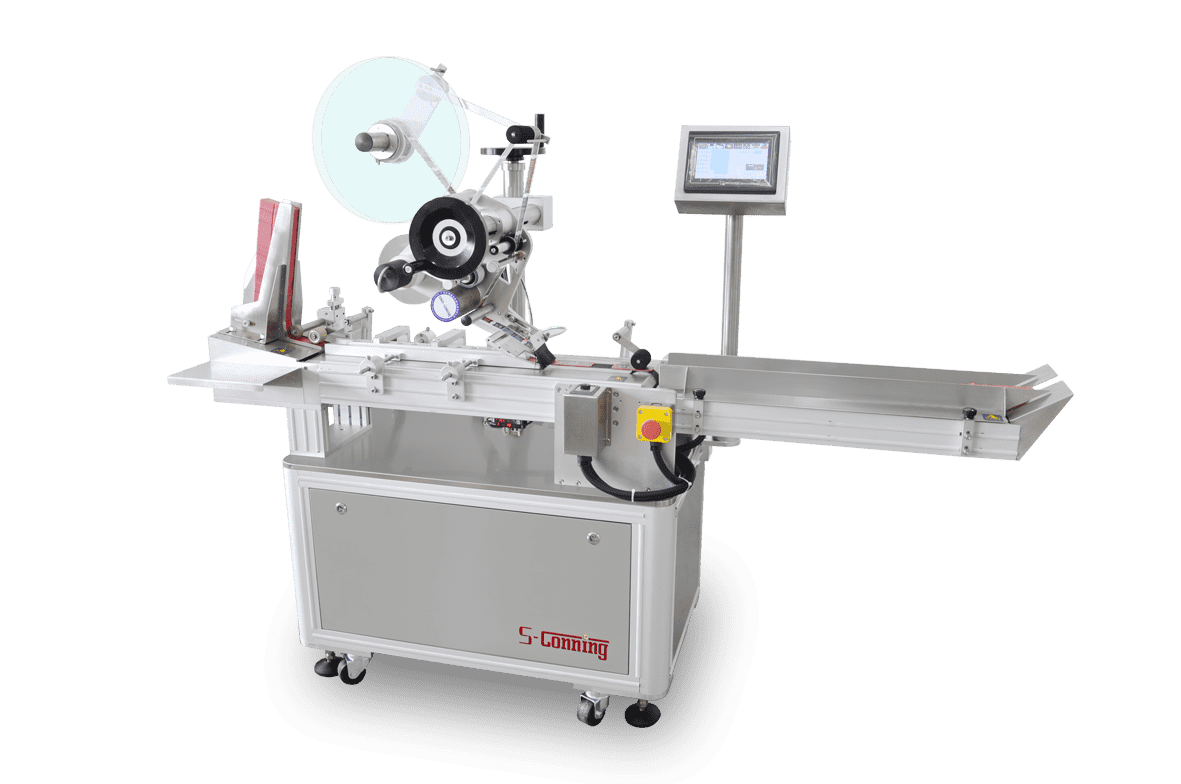

Factory source Automatic Bottle Cap Sealing Machine - liquid bottle packing machine – S-conning Detail:

SFZ Packing & Labeling Production Line

APPLICATION:

The SFZ packaging line is integrated with functions of high-speed horizontal labeling, on-site carton making, automatic horizontal carton input, punching and output automatic cartoning machine.

• S616Vertical Feeding & Vertical collecting Horizontal Round bottle labeler: Widely used for pharmaceutical industry for the ideal design of small round bottle high-speed automatic labeling and printing code , the stable speeds of up to 600 bottles / min.

• FZT384-molding machine:Forming machine to achieve the automatic complete blister packaging , testing and rejection and series of work . not only improved the running efficiency .also decreased the workload.

• Z130 Vertical automatic carton machine:The device is a integration of photoelectricity, pneumatics, mechanics high-tech products. Suitable for pharmaceutical, aluminium & plastic blister packaging Pharmaceutical products, a small body of regular long items, food, cosmetics and so on ,it can to be automatic cartoning , Can automatically complete boxes open, instruction book enfold , printing batch number, sealing and other complex packaging process.

Advantages:

-all electrical systems are equipped with safety marks, electrical equipment has a good grounding system.

-All imported brand electrical equipment is used, and the electrical installation plate is made of insulating material.

-This versatile liquid bottle packing machine applicable to various types of bottles,such as oral liquid bottles, ampoules, schering bottles and pen-injectors, etc., with diameter smaller than25mm.

ampoules, schering bottles and pen-injectors, etc., with diameter smaller than25mm.

-The complete machine adopts servo label equipment, with perfect implementation of intelligent linkage of forming, carton input and punching.

-PVC film feeding is controlled by servo system, one forming for each feeding,with precise control and eliminated unstable factors caused by mechanical structure.

-The unqualified carton can be detected by the detection mechanism of carton forming unit to avoid being input into the carton.

-The large HMl touch screen provides abnormal information display and trouble-shooting guidance, as well as simple operation and convenient maintenance.The machine can easily used by anyone.

-By simply replacing the mold, the carton making and input mechanism canproduce cartons with all sizes according to customer’s needs.

-The unqualified carton can be detected by the detection mechanism of carton forming unit to avoid being input into the carton.

extra performance

1) .PLC combined with human/machine interface LCD touch screen controller.

2). Stainless steel frame construction and components are standard.

3). Labeling speed is automatically synchronized with conveyor speed to ensure quality labeling.

4). 50 Job Memory for easy recall.

5). Precision servo motor drive on label heads.

6).Ensure GMP environmental requirements.

7).Professional HMI touch screen: more humanized touch control screen .

8).Label applicator be equipped with High quality servo motor .

Specifications:

| Power Supply | AC380V 50/6 OHz 3山 |

| Total Power | 12KW |

| Punching Frequency | 20-30/Min |

| Atmospheric Pressure | 0.6-1.0 Mpa |

| Specfication Of bottle/tray size | Can Design As The Requirement Of Customer |

| Size (L) x (W) x (H) | 8090mmx3220mmx1786mm |

| Labeling Capacity | 60pcs/min (10bottles)/tray |

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Factory source Automatic Bottle Cap Sealing Machine - liquid bottle packing machine – S-conning , The product will supply to all over the world, such as: Tunisia, Puerto Rico, Rwanda, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.