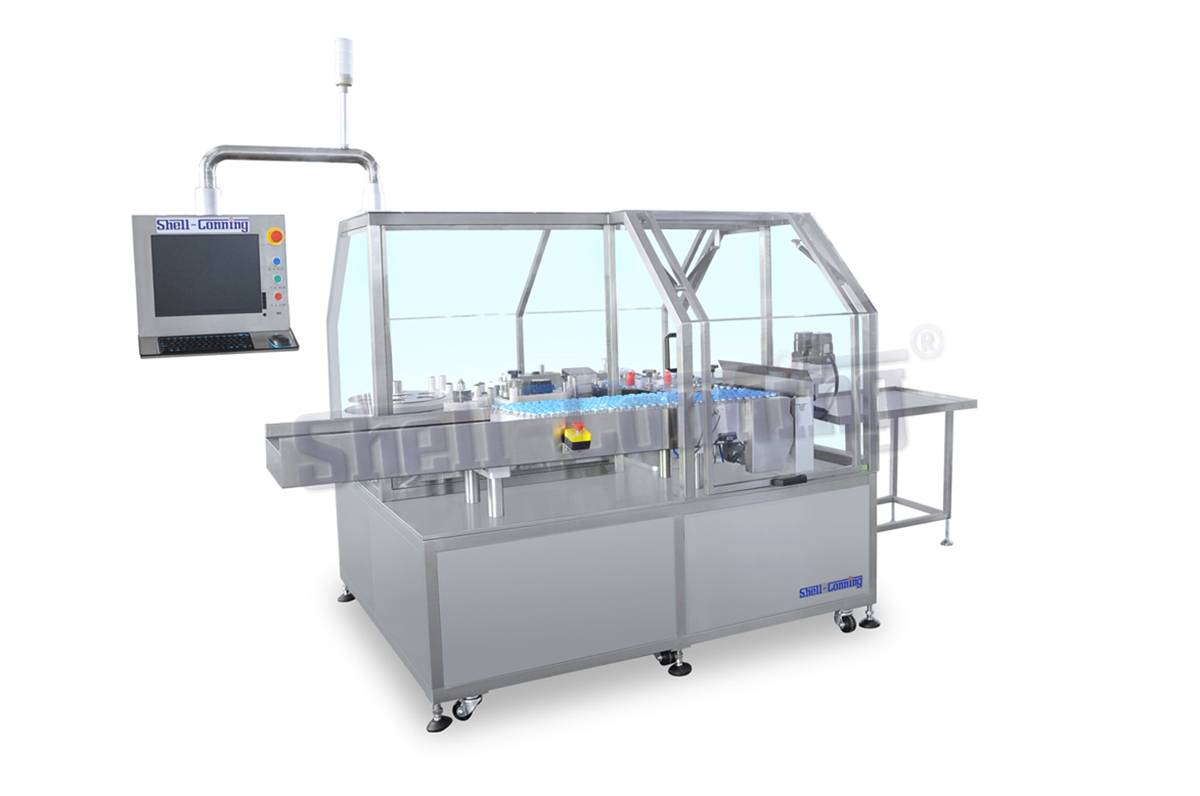

S307 High speed vial labeling machine

APPLICATION: high-speed precise labeling for vials and other small round bottles Methods of vertical feeding and transport of small containers by a screw conveyor are suitable for bottles which do not stand firmly and fall down easily.

•High-efficiency screw conveyor dynamic system ensures the vials feeding extra stability and high precision labeling at all speeds.

•Adopt air cylinder rejection device of,ensure can accurately detect and reject the unqualified products when the machine during high-speed running

• Especially for Lyophilized Powder production line, pharma production line and cryo vial labeling.

We offer you more than you desire

Labeling process controlled by Siemens micro process controller PLC, ensuring a fast and steady performance.

Label dispensing is driven by industrial grade servo motor (Yaskawa/Schneider/Honeywell) to ensure labeling accuracy, efficiency, and speed while being low on energy consumption. (For high speed demands, the servo motor can be selected)

Utilizes high-end branded fiber optics and infrared sensors (Keyence/Lion/Dalsa/Sick /Leuze) for precise detection and signal triggering without interference.

*Full servo engine dynamic system offer the maximum stability and accuracy.

*Applicable to all types of box or bottles with diameter 30-150mm.

*High-end component adoption from German, France, Japan, USA brands.

*Sensitive design and scientific structure.

*S-conning unique patent design, outstanding in the packing industrial.

*12 years experience, expert for debugging.

*Profound after-sale service.

* Labeling speed is automatically synchronized with conveyor speed to ensure quality labeling.

* 50 Job Memory for easy recall.

* Precision servo motor drive on label heads.

*Ensure GMP environmental requirements.

*Professional HMI touch screen: more humanized touch control screen

Optimal Configuration

The versatile S307 High Speed labeler is armed with the newest and fastest netcon control technology(optional). With just a click of its one-touch screen, you can easily adjust the various settings for your product needs.

-Our machine with servo drivers deliver accurate and high speed repeatable labeling. An easily accessible hand wheel adjuster and side rail quickset adjuster allows more “up-time” on your production line! The S307 is used in virtually all industries such as pharmaceuticals, personal care products, foods, vitamins, cosmetics, and chemicals, where best-in-class reliability is the mandate for producing efficiently.

Mature Technology

easy to operate and compact structure: Pause labeling when no object input, object position auto-correction when none of label, and the optional automatic detecting function.

The whole machine is control by the computer, automatic detecting target bottles with label synchronously, and equipment also can be equipped with the hot printing machine

adopt the horizontal distribution, sophisticated clamping belt labeling ensure the labeling precision and speed.

Features

From the design, very first time of operation, management, maintenance and the future production lines, S-conning think more for you and your company.

-Built in-operation manual: beginners can learn from the display on how to operate the machines within a short time.

This saves both money and time during training.

-Built in troubleshooting manual: the display would guide the user through troubleshooting.

-User-friendly label length set up system: The up-to-day HMI controls allows the user to set label parameters.

-Control system of labeler utilizes a large touch screen panel, certified by CE and UL regulations for efficient and effective monitoring of the labeling process.

-This unique and innovative system can guarantee that label setting are programmed accurately and applied onto the proper position.

-Labeling counter-keeps tracks of the quantity of products processed by the machine.

-Pre-set counter - a quantity can be preset for a production batch and the machine will automatically stop as the amount is attained.

-Simply touching the screen allows you to delay label application and adjust label position.

Maintenance is easy and efficient.

Sophisticated variable frequency drive controller ensure speed stability and ±0.5mm inaccuracy rate.

Guide rail portion is made with high quality aluminum covered with hard-wearing industrial plastic to ensure accurate labeling and product protection, keeping the customer’s product attractive and in perfect condition.

Labeler base is made of stainless steel to ensure full anti-rusting. This design ensures the machine and production space sanitation are maintained which is cater for GMP standards.

Wheels keep the machine portable, convenient when shifting to different production lines. This supportive mobile strength increases the value of your investment.

Specifications:

| Dimension | (L)2600 x (W)1500 x (H)1800mm |

| Container size | Φ13-40mm |

| Speed | 400~800bpm |

| Labeler accuracy | ± 0.5mm |